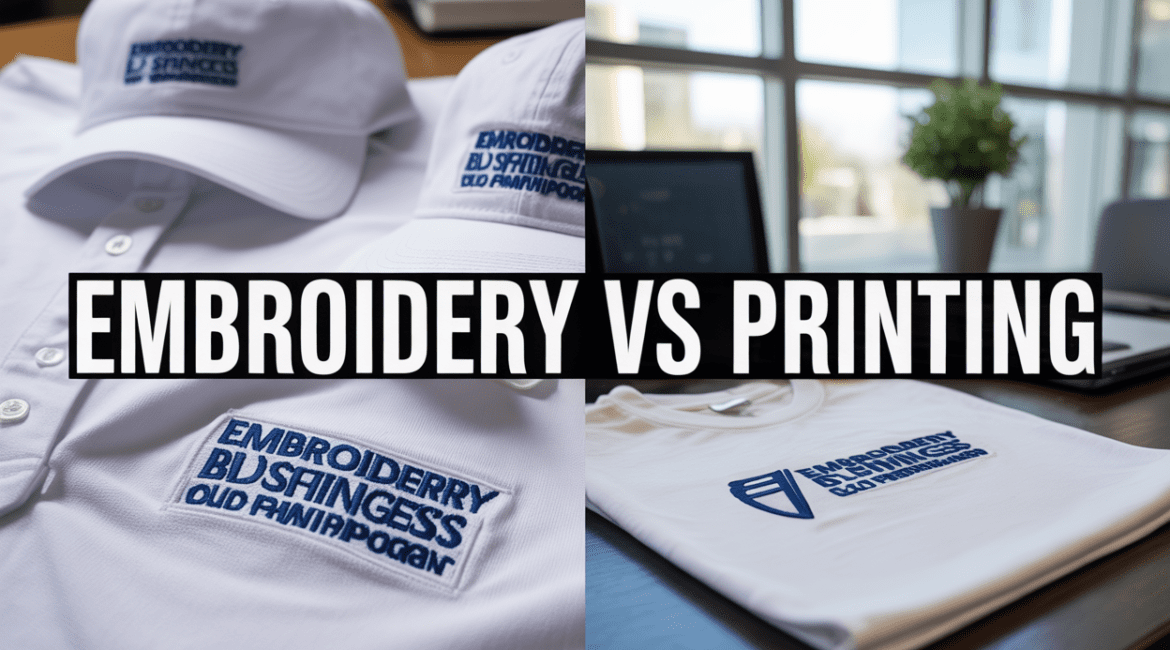

Choosing between embroidery vs printing for your business logo can make or break your brand’s

professional image. Business owners, marketing managers, and entrepreneurs need to understand

which method delivers the best results for their specific needs and budget.

This guide is designed for small business owners, corporate decision-makers, and anyone responsible

for ordering branded merchandise or uniforms. You’ll learn the key differences between these popular

logo application methods and discover which option works best for your situation.

We’ll break down the pros and cons of embroidery and printing techniques, then dive into the practical

factors that should guide your decision – like fabric type, order quantity, and intended use. You’ll also get

a clear comparison of how each method holds up over time, plus real-world scenarios to help you make

the smartest choice for different business applications.

Understanding Embroidery for Business Logos

Premium Quality and Durability Benefits

Embroidery delivers exceptional longevity that makes it an investment rather than just a decoration. The process involves stitching threads directly into fabric fibers, creating a permanent bond that won’t peel, crack, or fade like surface treatments. This durability means your logo maintains its crisp appearance through hundreds of wash cycles, making embroidered items perfect for uniforms that see daily wear.

The raised texture of embroidered logos creates visual depth and tactile appeal that immediately signals quality. Each stitch builds upon the previous one, forming a dimensional representation of your brand that catches light and draws attention naturally. This three-dimensional quality gives embroidery a premium feel that customers and employees associate with established, professional businesses.

Weather resistance is another major advantage. Rain, sun exposure, and temperature changes barely affect properly executed embroidery. The threads are designed to withstand commercial laundering and industrial cleaning processes, making embroidered logos ideal for workwear in demanding environments like construction, healthcare, and hospitality.

Professional Appearance That Builds Brand Credibility

Embroidery carries an inherent prestige that customers recognize immediately. The time-intensive process and skilled craftsmanship required create an automatic association with quality and attention to detail. This perception extends to your brand, suggesting that if you invest in high-quality logo presentation, you likely maintain similar standards in your products or services.

The clean, precise lines achievable through embroidery work particularly well for text-heavy logos and designs with fine details. Thread selection allows for subtle color variations and metallic accents that aren’t possible with other application methods. This versatility helps maintain brand consistency across different colored garments while preserving logo legibility.

Corporate environments especially benefit from embroidery’s polished appearance. Embroidered polo shirts, dress shirts, and blazers create a uniform professional image that builds trust with clients and customers. The permanent nature of embroidery also prevents the awkward situation of peeling or cracking logos during important meetings or presentations.

Cost Considerations for Different Order Quantities

Embroidery pricing follows a unique structure based on stitch count rather than logo size alone. Complex designs with intricate details require more stitches, increasing per-piece costs. Simple text or basic geometric shapes typically range from $3-8 per piece, while detailed logos can cost $8-15 or more.

Setup costs include digitization fees ranging from $15-50 for converting your artwork into machine-readable embroidery files. This one-time expense gets distributed across your order quantity, making larger orders more economical per piece. Orders of 50+ pieces often qualify for volume discounts that can reduce per-piece costs by 20-40%.

Small quantity orders face higher per-piece costs due to machine setup time and thread changes required for each color in your logo. However, many businesses find the professional appearance justifies the premium, especially for management uniforms or client-facing staff apparel. Reorder costs are typically lower since digitization files can be reused indefinitely.

| Order Quantity | Per-Piece Cost Range | Setup Fee | Best For |

|---|---|---|---|

| 1-24 pieces | $8-15 | $25-50 | Executive uniforms, samples |

| 25-99 pieces | $5-12 | $15-35 | Small teams, specialty items |

| 100+ pieces | $3-8 | $15-25 | Staff uniforms, promotional items |

Best Fabric Types and Garment Compatibility

Cotton and cotton blends provide the ideal foundation for embroidery work. The natural fiber structure holds stitches securely while allowing needles to penetrate cleanly without damaging the fabric. Polo shirts, button-downs, and canvas jackets made from cotton or cotton-poly blends consistently produce the best embroidery results.

Performance fabrics require special consideration. Moisture-wicking polyester and athletic materials can pucker or distort under embroidery tension. However, modern stabilization techniques and specialized threads make embroidery possible on most technical fabrics. Lightweight materials like performance tees may need backing material to prevent the design from showing through.

Knit fabrics present unique challenges due to their stretch properties. T-shirts and hoodies require careful handling to prevent distortion, but proper hooping and stabilization produce excellent results. Dense knits like fleece work exceptionally well with embroidery, as the fabric thickness supports detailed designs without puckering.

Avoid embroidery on very lightweight materials (under 4.5 oz), highly stretchy fabrics, or garments with extensive texture or pile. Mesh jerseys, silk items, and heavily textured materials don’t provide adequate stability for clean embroidery execution. These items work better with heat transfer or screen printing applications.

Exploring Printing Options for Logo Application

Versatility across multiple materials and surfaces

Printing technology opens up a world of possibilities when it comes to logo application. Unlike embroidery, which works best on fabric surfaces, printing can adapt to almost any material you throw at it. Think about the different touchpoints your customers have with your brand – business cards, promotional mugs, vehicle decals, metal signs, plastic products, glass surfaces, and even unconventional materials like wood or leather.

Screen printing works beautifully on textiles, creating vibrant designs on t-shirts, hoodies, and canvas bags. Digital printing excels on paper products, banners, and promotional materials. Heat transfer vinyl can transform any fabric item into a branded piece, while UV printing handles rigid materials like acrylic, metal, and glass with ease.

This flexibility means you can maintain consistent branding across your entire product line and marketing materials. Your logo can appear identical on a business card, a storefront window, and a company vehicle – something that would be impossible with embroidery alone. The ability to print on curved surfaces, textured materials, and items of varying thickness gives businesses creative freedom to explore unique promotional products and signage options.

Cost-effective solutions for large volume orders

When your business needs hundreds or thousands of branded items, printing becomes the clear winner from a budget perspective. The setup costs for most printing methods remain relatively fixed whether you’re producing 50 pieces or 5,000, which means your per-unit cost drops significantly as quantities increase.

Screen printing, for example, requires creating screens for each color in your design. While this initial investment might seem steep for small orders, it becomes incredibly economical for large runs. A single screen can produce thousands of impressions, bringing the cost per piece down to mere cents for basic designs.

Digital printing eliminates setup costs entirely for many applications. You can print one piece or one thousand with the same efficiency, making it perfect for businesses that need flexibility in their order quantities. This technology also allows for variable data printing, where each piece can have slightly different information – think employee name tags or numbered promotional items.

| Printing Method | Best Volume Range | Typical Per-Unit Cost |

|---|---|---|

| Screen Printing | 100+ pieces | $2-8 per piece |

| Digital Printing | 1-500 pieces | $5-15 per piece |

| Heat Transfer | 1-100 pieces | $3-12 per piece |

Full-color design capabilities and photographic reproduction

Printing technology shines brightest when your logo incorporates multiple colors, gradients, or photographic elements. Modern printing methods can reproduce virtually any color combination with stunning accuracy, making them ideal for complex brand marks or logos with intricate details.

Four-color process printing (CMYK) can recreate millions of color variations, allowing businesses with colorful, detailed logos to maintain their visual integrity across all applications. This capability becomes essential for companies whose branding includes photographic elements, realistic illustrations, or subtle color transitions that embroidery simply cannot achieve.

Spot color printing offers another advantage – the ability to match exact Pantone colors for perfect brand consistency. Whether your logo features a specific shade of corporate blue or a unique color that sets you apart from competitors, printing can nail that exact hue every time.

High-resolution printing also means fine text remains crisp and readable, even at small sizes. Company taglines, website addresses, or detailed graphics that would be impossible to embroider clearly can be printed with sharp precision. This level of detail reproduction makes printing the go-to choice for businesses with sophisticated brand identities that rely on visual complexity to communicate their message.

Key Factors That Influence Your Logo Method Decision

Budget Constraints and Long-Term Cost Analysis

Your budget plays a huge role in choosing between embroidery and printing for your business logos. Embroidery typically costs more upfront because it requires digitizing your design and has higher per-item costs. However, embroidered logos last longer and maintain their appearance through countless washes, making them a solid investment for items that get heavy use.

Printing methods like screen printing become more cost-effective with larger orders, while heat transfer and direct-to-garment printing work better for smaller quantities. When you factor in replacement costs over time, embroidery often wins for items like uniforms and jackets that employees wear daily. Printed logos might need replacing sooner, especially on garments that go through frequent washing cycles.

Consider your annual logo application needs and calculate the total cost over 2-3 years. This bigger picture often reveals the true value of each method.

Intended Use and Garment Longevity Requirements

The way your employees or customers will use logoed items dramatically affects which method works best. Work uniforms, outdoor gear, and items exposed to harsh conditions benefit from embroidery’s durability. The raised threads resist fading, cracking, and peeling that can plague printed designs.

Promotional items, event t-shirts, or seasonal merchandise often work perfectly with printing methods. These items typically have shorter lifespans and don’t need to survive years of wear. Athletic wear presents unique challenges – embroidery can feel stiff and uncomfortable during physical activity, while specialized printing methods designed for sportswear offer flexibility and moisture-wicking properties.

Think about how often items will be washed, whether they’ll face outdoor elements, and the physical demands placed on the garments.

Brand Image and Target Audience Expectations

Your brand’s personality and your audience’s expectations should guide your logo method choice. Embroidered logos convey professionalism, permanence, and quality. They work exceptionally well for corporate settings, medical facilities, restaurants, and service industries where trust and credibility matter most.

Printed logos offer more flexibility for creative, colorful designs and can capture the energy of younger, trend-focused brands. Tech companies, creative agencies, and retail brands often prefer printing for its ability to reproduce complex graphics and vibrant colors.

Consider what your customers expect when they see your brand. A law firm’s polo shirts with embroidered logos send a different message than a skateboard shop’s screen-printed tees.

Design Complexity and Color Requirements

Your logo’s design complexity significantly impacts which method will work best and look most professional. Embroidery excels with simple, bold designs featuring 2-4 colors. Text-heavy logos, intricate details, and gradients don’t translate well to embroidery and can look cluttered or lose important details.

Printing methods handle complex designs, photographs, and unlimited colors beautifully. Screen printing works great for designs with solid colors, while digital printing can reproduce the most detailed artwork with photographic quality.

| Design Type | Best Method | Considerations |

|---|---|---|

| Simple text/logo | Embroidery | Clean, professional appearance |

| Multi-color graphics | Digital printing | Unlimited color options |

| Fine details | Heat transfer | Crisp reproduction |

| Gradients/photos | Direct-to-garment | Photo-quality results |

Order Quantity and Timeline Considerations

Your order size and deadline requirements can make the decision for you. Screen printing becomes cost-effective with orders of 50+ pieces but requires longer setup times. Embroidery works for any quantity but takes longer per piece for complex designs.

Digital printing and heat transfer excel for small batches and quick turnarounds. You can often get printed items within days, while embroidered pieces might take 1-2 weeks depending on design complexity and order size.

Rush orders favor printing methods, especially for simple designs. Embroidery shops need more time for setup, digitizing, and the actual stitching process. Plan ahead if you’re leaning toward embroidery, especially during busy seasons when turnaround times extend.

Comparing Performance and Longevity

Wash Durability and Fade Resistance Comparison

Embroidered logos stand as champions when it comes to surviving countless wash cycles. The thread construction creates a physical barrier that protects against detergent chemicals and mechanical washing action. Quality embroidery thread maintains its color integrity for years, resisting fading even under harsh washing conditions.

Screen printing shows variable performance depending on the ink type and fabric preparation. Water-based inks may crack or peel after repeated washing, especially if applied incorrectly. Plastisol inks offer better durability but can still deteriorate over time. Heat transfer vinyl provides moderate wash resistance but tends to lift at edges after multiple cycles.

Digital printing presents mixed results – some advanced inks bond well with fabric fibers, while others may fade or wash out completely. The substrate and pre-treatment process significantly impact longevity.

| Method | Wash Cycles | Fade Resistance | Color Retention |

|---|---|---|---|

| Embroidery | 100+ | Excellent | 95%+ |

| Screen Print | 50-75 | Good-Fair | 80-90% |

| Heat Transfer | 25-50 | Fair | 70-85% |

| Digital Print | 20-40 | Variable | 60-80% |

Professional Appearance Retention Over Time

Embroidered logos maintain their crisp, professional appearance longer than any printing method. The dimensional quality of stitched thread creates texture that doesn’t flatten or wear down with use. Even after months of regular wear, embroidered logos retain their structured appearance and sharp definition.

Printed logos face different challenges. Screen printing can develop micro-cracks that become more visible over time, creating a weathered look that may not suit professional environments. The flat surface of prints is more susceptible to abrasion and surface wear.

Heat transfer applications often show their age through edge lifting, cracking, or complete separation from the garment. The plastic-like feel of some transfers can become brittle, leading to flaking or peeling that creates an unprofessional appearance.

Digital prints vary widely in their aging characteristics. High-quality digital printing can maintain decent appearance for moderate periods, but lower-grade applications may show significant deterioration within months.

Maintenance Requirements and Care Instructions

Embroidered items require minimal special care. Standard washing and drying procedures work well, though turning garments inside out protects the stitching from excessive friction. Avoid fabric softeners that might coat the threads and dull their appearance.

Screen printed garments need more careful handling. Wash in cool water with mild detergents, and avoid bleach or harsh chemicals. Turn items inside out before washing to protect the print surface. Air drying extends the life of screen prints significantly compared to machine drying.

Heat transfer applications demand the most careful treatment. Use cold water washing, gentle cycles, and avoid fabric softeners entirely. Never iron directly over transfers, and consider air drying to prevent heat damage that could cause lifting or cracking.

Digital prints benefit from similar care to screen prints – cool water, gentle detergents, and minimal heat exposure during drying. Some digital prints may require specific care instructions based on the ink system used.

Making the Right Choice for Different Business Scenarios

Corporate uniforms and professional wear recommendations

Corporate environments demand a polished, sophisticated appearance that reflects company values and maintains professional standards. Embroidery stands out as the clear winner for corporate uniforms, business attire, and executive wear. The raised texture and premium feel of embroidered logos instantly communicate quality and attention to detail that clients and customers notice.

For dress shirts, polo shirts, and blazers, embroidery creates a subtle yet impactful brand presence. The three-dimensional effect works particularly well on collars, chest areas, and sleeve cuffs where the logo needs to maintain its shape and appearance through repeated washing and professional cleaning. Corporate uniforms often go through rigorous care cycles, and embroidery’s durability ensures the logo remains crisp and professional-looking for years.

Executive gifts and high-end corporate merchandise also benefit from embroidery’s premium appeal. Items like leather portfolios, high-quality jackets, and business accessories gain perceived value when decorated with embroidered logos rather than printed alternatives.

Promotional items and marketing merchandise strategies

Marketing merchandise requires a strategic approach based on budget, quantity, and intended impact. Screen printing dominates large-scale promotional campaigns due to its cost-effectiveness and ability to handle massive quantities. T-shirts, tote bags, and basic promotional items work perfectly with screen printing, especially when you need thousands of pieces for trade shows, events, or community outreach.

Heat transfer vinyl offers flexibility for smaller promotional runs or when you need multiple color variations. This method works well for seasonal campaigns, limited-edition merchandise, or when testing new designs before committing to larger quantities.

Digital printing shines for promotional items requiring photographic images, gradients, or complex multicolor designs. Business cards, brochures, and high-end promotional materials benefit from digital printing’s precision and color accuracy.

Consider your audience when choosing methods. B2B promotional items often warrant embroidery’s premium feel, while consumer-focused giveaways might prioritize quantity over premium finishing, making screen printing the practical choice.

Retail apparel and customer-facing products

Retail apparel presents unique challenges since customers directly purchase and evaluate these products. The decoration method significantly impacts perceived value, pricing strategy, and customer satisfaction. Understanding your target market’s expectations helps determine the right approach.

Premium retail brands typically favor embroidery for its upscale appearance and durability. Customers paying higher prices expect quality that extends beyond the base garment to include professional logo application. Embroidery meets these expectations while justifying premium pricing.

Fashion-forward brands often choose screen printing or digital printing for artistic designs, trendy graphics, or seasonal collections. These methods allow for creative freedom with colors, effects, and design complexity that embroidery cannot achieve.

Athletic and activewear brands frequently combine methods – using embroidery for logos and brand marks while employing screen printing or heat transfer for larger graphics, numbers, or performance-related messaging.

Consider your brand positioning carefully. Luxury brands risk damaging their reputation with cheap-looking printed logos, while budget-conscious brands might find embroidery too expensive for their price points.

Event merchandise and temporary branding needs

Events create unique branding opportunities with specific timeline and budget constraints. The temporary nature of most event merchandise influences decoration method selection significantly.

Concert merchandise, festival apparel, and event commemoratives often use screen printing for its ability to handle rush orders and large quantities cost-effectively. Event organizers typically need hundreds or thousands of pieces produced quickly, making screen printing’s efficiency essential.

Heat transfer vinyl works well for last-minute changes, personalization options, or when event details change close to production deadlines. This method allows for quick adjustments to dates, sponsors, or event information without scrapping entire production runs.

Corporate events and conferences might warrant embroidery for VIP gifts, speaker gifts, or high-value attendee merchandise. The premium feel enhances the event’s perceived value and creates lasting positive impressions.

Pop-up shops and temporary retail situations benefit from printing methods that allow for quick production and easy inventory management. Digital printing enables on-demand production, reducing waste and allowing for real-time design adjustments based on customer feedback.

Sports tournaments and competitions often combine embroidery for team uniforms with screen printing for fan merchandise, creating different quality tiers that match various budget levels and intended uses.

Conclusion

Embroidery offers a premium, professional look that works best for corporate wear and industries where quality perception matters most. It’s durable and gives your brand a high-end feel, though it comes with higher costs and some design limitations. Printing, on the other hand, gives you incredible flexibility with colors and detailed designs while keeping costs down, making it perfect for promotional items and large quantity orders.

The choice between these two methods really comes down to your specific needs. Think about your budget, the types of items you want to brand, and how your customers will use them. If you’re outfitting a sales team with polo shirts, embroidery might be worth the investment. But if you’re creating event giveaways or need vibrant, complex designs, printing will serve you better. Test both options with small orders first to see which one best represents your brand and resonates with your audience.